A Brief History of Dry Ice and Dry Ice Blasting

Dry ice was discovered by accident in 1835 by a scientist names Thilorier. He had intended to observe the qualities of liquid carbon dioxide and, instead, ended up observing it went from a solid to a gas immediately. Thus discovering the dry ice we know today. While it was used in the science world for study, it didn’t move beyond experimental use until the late 1800s.

Although it might seem like dry ice blasting is new on the commercial cleaning scene, it has actually been around since the 1920s, but it wasn’t nearly as safe as it is now. Prest Air Devices made the first application for commercial use with the invention of their carbon dioxide fire extinguisher, along with other dry ice products. We have since seen dry ice move into many more uses, including dry ice blasting machines, a tool which has quickly become our team’s favorite way to clean.

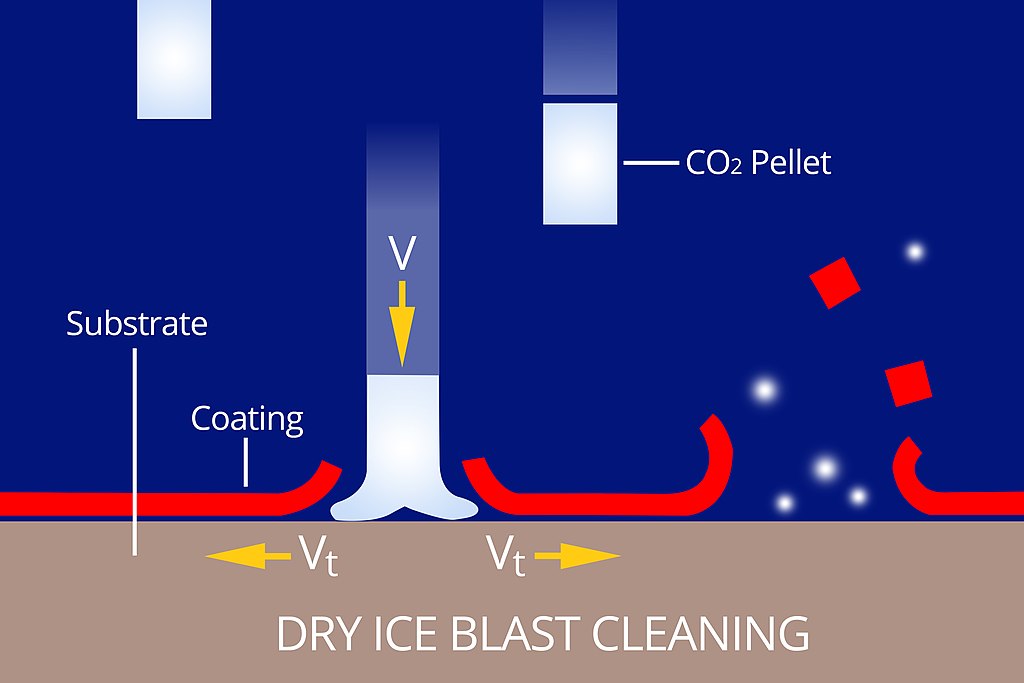

Benefits of Dry Ice

Dry ice has a lot of benefits that make it preferable to sand for blasting.

- It’s cold, which enhances it’s ability to clean.

- It is safe and non-toxic, making it a food grade cleaner and safer than chemicals.

- It’s sustainable for the environment because it’s made from recycled CO2 and it doesn’t pollute CO2 into the atmosphere.

- There is no secondary waste with dry ice, therefore it doesn’t leave behind an even bigger, moist mess to clean up.

- It’s colorless, odorless, and tasteless so it doesn’t bother the area being cleaned, the applicator, or those in the vicinity of the dry ice.

The Benefits of Dry Ice Blasting

Dry Ice Blasting has many benefits as a cleaning method.

- It’s non-abrasive, so it keeps even the softest surfaces safe.

- It’s operator safe, meaning there are no chemicals harmful to skin or dangerous fumes that could be breathed in.

- It’s a very quick process compared to traditional methods, reducing downtime.

- Dry ice is a food grade media making it safe to use on commercial food production lines.

- The process is time efficient, saving labor costs for the project.

- Dry Ice blasting has endless applications like:

- Asphalt Removal

- Automotive Restoration

- Coatings & Corrosion Removal

- Coffee Roaster Cleaning

- Commercial Food Line Cleaning

- Composite Tool Cleaning, Core Box Cleaning

- General Equipment Cleaning

- Historical Restoration

- Mold Cleaning

- Nonwoven Die Cleaning

- Parts Finishing

- Remediation (Water or fire damage)

- Surface Preparation

- Weld Line Cleaning