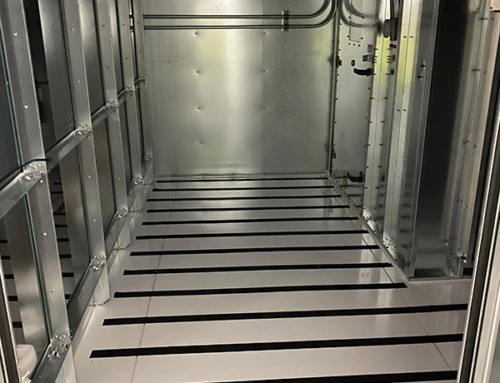

Automated conveyor cleaning is on the rise for daily cleaning and why this huge time saving invention is great for daily cleaning, it doesn’t begin to scratch the surface of a deep clean. Man power is still the best way to get a through, deep clean for your entire conveying system.

Conveyor Maintenance

In addition to a great clean, manual conveyor cleaning allows for every part of the conveyor system to be easily inspected. It’s easy to catch parts that need to be replaced or repaired during a full system, in-depth cleaning allowing your system to remain at peak performance. The conveying system needs to be broken down as much as possible to get the best clean possible. During the reassembly, anything that had become misaligned can be corrected, allowing even wear on the conveyor.

Safety

Aside from protecting the conveyor itself, cleaning helps to ensure the safety of the employees, products, and consumers. When the conveyor is regularly inspected on a part-by-part level, it aids in preventing unexpected accidents due to faulty or worn parts. A thoroughly deep cleaned conveyor prevents any build up of combustible dust, protecting both the workers and the facility.

Products run on a conveyor are protected with regular cleaning as they ensure the products are as pure as possible. This is especially important when it comes to food, medical supplies and pharmaceuticals. For both food and pharmaceuticals, a clean line is paramount. Consistent deep cleaning prevents cross-contamination, from pathogens and other products, resulting in fewer recalls for companies.

Consumers benefit from conveyor cleaning because it helps keep goods safe for use and consumption. Consistent cleaning helps prevent deadly bacteria from infecting food sources and medications. The millions of people living with food allergies particularly benefit from proper cleaning as it allows them to safely consume foods made in the same facility or on the same line.

Summary

Conveyor cleaning provides many benefits to companies, employees, and consumers. Companies who complete thorough cleanings on a regular basis help to aid in the protection of their equipment, workers, and the people purchasing their products. Conveyors are able to stay in good working condition for longer, employees experience safer work environments, and consumers are kept safe from harmful pathogens and allergens.

Have a conveyor and want to learn more about how Clear Air Enviro-Services can help with your regular cleaning and maintenance schedule? Contact us today!