This month we, Clear Air Enviro-Services, are diving into all things cooling towers. What are they? What do they do? How do they work? What industries are they used for? How do you clean them? Read on to learn more!

Cooling Towers for Process Cooling

What Are Cooling Towers and What Do They Do?

Simply put, Cooling Towers are heat removal devices that remove unwanted heat from chillers.

How Do Cooling Towers Work For Process Cooling?

Cooling Towers use water as a heat transfer mechanism and as a result, the heat is removed from the water supply through evaporation. Inside the cooling tower, air moves through the plates housed inside and over the water. This is then pumped to the top of the tower and moves down flow plates to the basin. When the air passes over the water, the heat is released from the air, into the water, and then evaporates as the air continues to cycle through the cooling tower. When the warm water and cool air mix, the latent heat from vaporization is released.

What Industries Use Cooling Towers For Process Cooling?

Some of the industries that require process cooling include:

- Chemical Processing

- Steel Mills

- Power Plants

- Manufacturers

- Refineries

- National Gas Processing

- Food Processing

Cooling Towers for Commercial HVAC

How Do Cooling Towers Work For Commercial HVAC?

When it comes to large commercial spaces, traditional air commercial HVAC units are not fully equipped to keep the buildings cool and that is where Commercial cooling towers come into play. Commercial cooling towers for HVAC purposes are filled with condenser coils that generate a lot of heat as the system cycles. Cold water moves through the warm coils and then into a heat exchanger that pulls heat from the water. It then pushes the it back to the coils which reduces the strain on the system as a whole. Commercial HVAC Cooling Towers take pressure off of the main HVAC system so that it works more efficiently and effectively with fewer breakdowns.

What Facilities Use Cooling Towers For Commercial HVAC?

Commercial Facilities Include:

- School Buildings

- Hotels

- Hospitals

- Airports

- Office Buildings

- Event Centers

How Do You Clean A Cooling Tower?

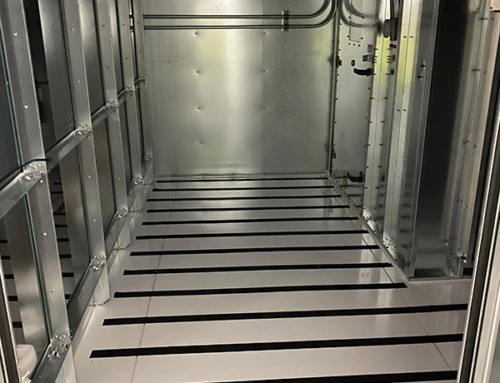

Cooling towers should be cleaned twice per year at a minimum to prevent the buildup of scale deposits, bacterial growth, and sludge. Prior to cleaning, it is important to complete an inspection of the cooling tower. This helps our team know the areas that need to be treated with more chemicals to mitigate the present issues. Once the inspection is complete, we begin to properly disinfect and thoroughly clean the interior of the cooling tower. We treat the coils with a special chemical that kills bacteria and mold on the coils inside the tower and prevents the bacteria from circulating throughout the air. The chemicals we use will not damage the fill media, so the lifecycle of the fill media can be as long as possible. We will pressure wash the outside of the tower and thoroughly clean the sludge out of the basin to ensure the entire cooling tower is clean and ready for its season of either use or dormancy. The entire cleaning process is documented in both a written and photographic form so that you can see the before and after for each section of the tower. We keep a detailed log of problem areas for the future so we know which areas to pay special attention to moving forward.

Ready to Schedule your fall cooling tower cleaning? Send us a message or give us a call today! P.S. Ask us how you can save with our cleaning tower cleaning subscription program!